Our team will contact you!

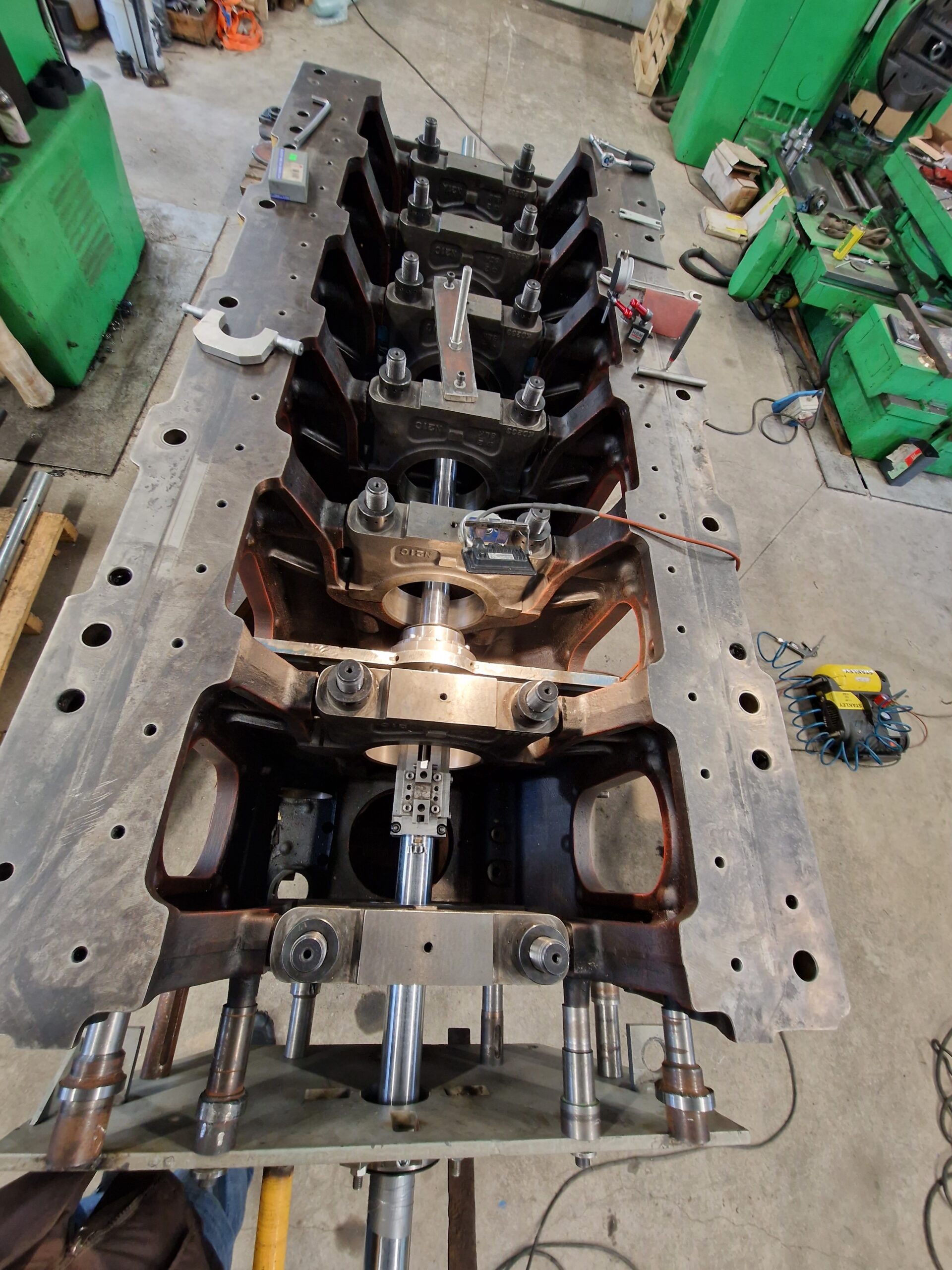

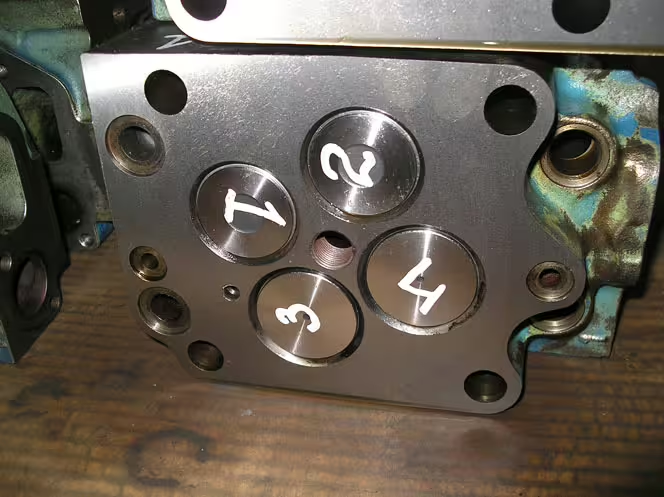

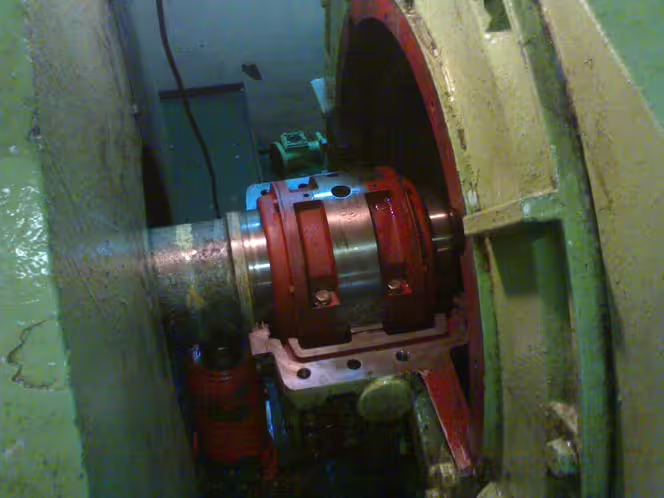

Yanmar 6N21 engine frame bearing seats were restored.

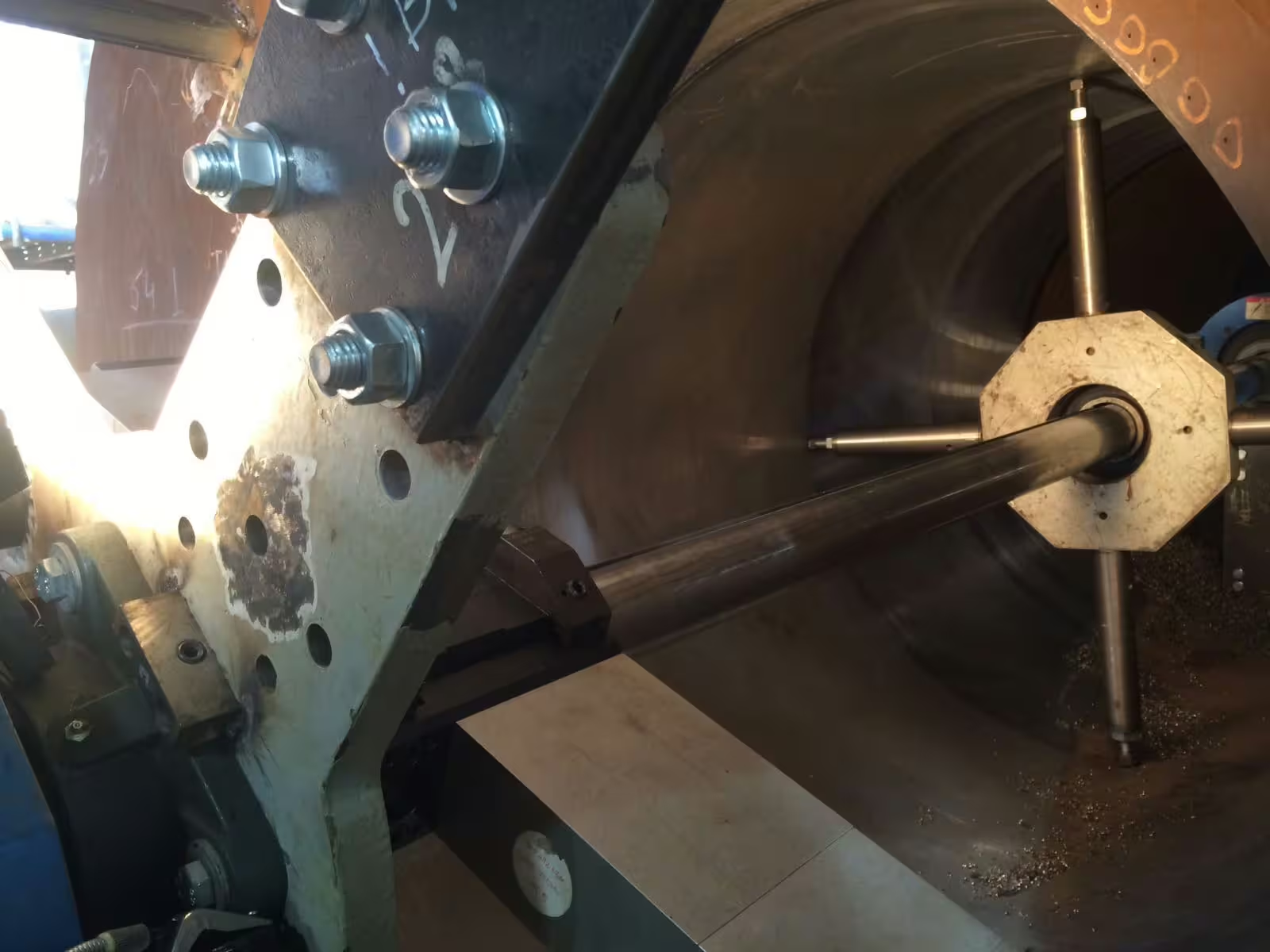

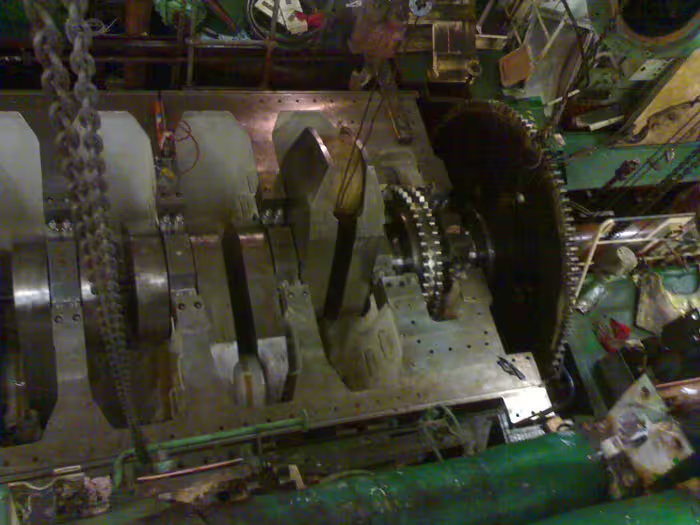

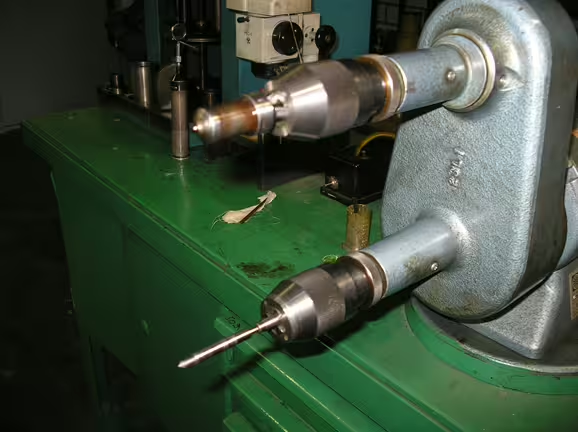

Inspection of connection surface of Yanmar 6N21 engine block with foundation frame and crankshaft axis was measured by using laser equipment. Based on measurement results main bearing caps were grinded and line boring of main bearing pockets was performed into nominal size.